Mine safety officials subject of federal probe

July 21, 2005

Scranton, PA (AP) - The U.S. Labor Department is investigating whether the two federal officials responsible for ensuring safety in Pennsylvania's few remaining underground anthracite mines have been harassing mine operators and unfairly driving some out of business - a probe that follows long-simmering tensions in the coalfields between miners and their regulators.

Federal investigators have confiscated the computers of the two officials and interviewed miners and inspectors amid allegations that the regulators have retaliated against miners who challenged them and improperly pressured inspectors to find violations, The Associated Press has learned through interviews with inspectors, miners and the miners' attorney.

Deep mine operators say that the Mine Safety and Health Administration's District 1 manager, John Kuzar, and his assistant, William Sparvieri, have made it difficult if not impossible for them to stay in business. Some owners have closed their mines because they say they were unwilling or financially unable to fight the agency in court.

Deep anthracite mining in Pennsylvania is in danger of extinction, hurt over the decades by steeply declining market share and now by what operators say is heavy-handed enforcement. Only about a dozen working underground anthracite mines are left, down from 60 in 1995 and 140 a decade earlier.

The conflict between the mine operators and the Wilkes-Barre office of the federal mining agency has its roots in the uniqueness of underground anthracite mining.

Eastern Pennsylvania has the nation's only deposits of anthracite, a hard coal that once heated millions of homes and kept tens of thousands of miners employed. But the federal law dealing with mine safety is geared toward bituminous coal, a soft coal found throughout the country that has long dominated the sector.

Because bituminous coal and anthracite coal are mined differently, federal inspectors in the past regularly made exceptions for the tiny anthracite mines. But the agency began strictly interpreting and enforcing the law after Kuzar and Sparvieri, both of whom hailed from the bituminous coalfields, were installed in the agency's Wilkes-Barre office in 2000 and 2001.

A spokeswoman for the Mine Safety and Health Administration said the agency, which is part of the Labor Department, would have no comment on the investigation. Kuzar declined comment Thursday. "I don't know what it's all about," he said.

In a February response to an inquiry by Sen. Rick Santorum, R-Pa., the agency denied the miners' and inspectors' allegations.

"It is neither MSHA's mission nor practice to drive anthracite mines out of business or be retaliatory," wrote David G. Dye, acting chief of the agency.

The miners' lawyer, Adele Abrams, said Kuzar was furious about being transferred from Denver - where he had headed the agency's largest mining district - to the smallest district, and has taken out his wrath on the mine operators.

"It's almost become a Captain Ahab vendetta," she said. "You get the sense that Kuzar's ... last act will be to put the padlock on the last anthracite mine in America. And that would be a shame."

Former mine inspector Robert Dudash recently spoke for three hours with investigators from the Labor Department's Office of Inspector General. He said they wanted "any information of any improprieties that would have happened concerning Kuzar and Sparvieri. ... I gave them everything that I had."

Dudash, a mine operator for more than 20 years before joining the mine safety agency in 1998, said he told investigators about instances in which he was pressured to find mine owners in violation of the federal mine safety law, regardless of whether they actually were.

Two current mine inspectors, who also were interviewed by Labor Department investigators, said they provided information about similar tactics. The inspectors spoke to AP on condition of anonymity because they are still employed by the mining agency.

Dudash said that in one case, Kuzar and Sparvieri ordered him to write a citation for a Schuylkill County mine where an accident had occurred, even though he and his supervisor could not find any violations of the law.

The mine owner appealed the citation and the agency's solicitor ultimately told the Wilkes-Barre office to drop it. Dudash said Sparvieri then sent an inspector to the same mine to write four or five more citations.

"It was retaliation," Dudash told the AP.

On another occasion, Dudash alleges he was ordered to testify in court that he believed a mine operator had knowingly broken the law - thus potentially subjecting her to criminal penalties - but that he resisted because he did not believe that to be the case.

"That was pretty much the beginning of my demise," he said. "From that point on I was labeled a dirty inspector."

Dudash said he took a medical leave of absence in 2003 after the stress of the job had become too great. He said he was fired in 2004 - two days before Christmas - after he refused an order from Kuzar and Sparvieri to return to work.

Dudash said he most likely could have gotten his job back as part of a recent settlement of an administrative complaint he filed against Kuzar and Sparvieri, but chose not to return. He now runs an excavating company.

Dudash said that when he told Sparvieri that his actions in one case would likely force the mine to close, Sparvieri and another manager in Wilkes-Barre said it shouldn't be his concern.

Another inspector said investigators asked him several questions about the treatment of the Rothermel family, whose Pottsville-area mine has been shut down seven times this year for purported health and safety violations. The Rothermels have been among the most vocal critics of District 1 management.

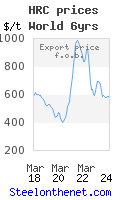

The price of anthracite is as high as it has even been and demand is strong; it is largely used in home heating, to generate electricity and for other industrial purposes. But, the inspector said, he told investigators that former mine operators have told him they would not re-enter the business unless Kuzar and Sparvieri were removed from the district office.

Abrams, the miners' attorney, is a certified mine safety professional who has given training seminars to federal inspectors. She said huge bituminous coal mining companies with spotty safety records have received far less federal scrutiny than the tiny anthracite mines, which are mostly family-owned and operated.

"Sometimes I can't even come up with the words to describe how unreasonable this enforcement action is and how aberrant it is," she said.