European Green Party fights steelmakers on climate change

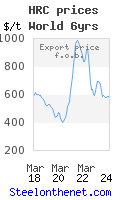

Europe's steel industry – say the Greens - is caught in the grips of the economic crisis. With reduced industrial activity, the demand for steel has plummeted. Since the beginning of the Great Recession, steel demand in the EU-27 has dropped by around 25 per cent. Simultaneously, new industrial powerhouses such as China and India have increased their share in the global steel market, putting pressure on European steel companies. This has hit the European industry hard. According to the Greens however the industry seems to have mistakenly believed that it would enjoy its preeminent position with a constantly growing world hunger for steel ad infinitum.

Now – say the Greens – the sector is struggling to find a way out of this dilemma. Restructuring efforts such as closing down production sites or reducing output has shed about 40.000 jobs. Yet, the steel sector is not recovering. As a truly European industrial sector with over 500 production sites split between 23 EU member states, the steel industry has appealed to the European Union for help in these difficult times.

Regrettably, instead of addressing the root problem of the situation - depressed demand, over-capacity and a lack of a movement to higher value-added steel production - the industry has made the EU's climate and energy framework responsible for its conundrum. Climate and energy policies - from the steel industries' perspective 'are destructive, are badly constructed and have to be changed'. The steel industry in particular calls on the EU to revisit its policies to bring down energy prices for industry, which they say have increased due to the EU's climate and energy framework such as the emissions trading system. Dr Eder, CEO of the Austrian steelmaker Voest Alpine, has said that EU climate and energy policies are among the main causes for the deindustrialisation in Europe.

This short-sighted approach is – suggest the Greens - faulty in two fundamental ways. First and foremost, it does not take into account the large variety of exemptions and free CO2 allocations that the steel industry enjoys, which cushions the impact on energy prices. According to an analysis by the Oeko-Institute, energy-intensive industry in Germany such as steel receives a CO2-cost compensation; receives free CO2 emission allowances that can be sold for a profit or banked for the future given that production has decreased; and is exempt from paying fees for energy network use. Combined with the fact that the increase in renewable energies has actually over time led to a decrease in energy prices of about 10 €/MWh, the Oeko-Institute comes to the conclusion that the energy-intensive sector in Germany would [with a smart energy procurement strategy] almost reach parity with its counterparts in the US when it comes to energy prices.

Secondly, by attacking the energy and climate agenda, the European steel industry is actually undermining the very agenda that provides a vision for addressing the overcapacity crisis which it is facing. It's simple: the European steel sector has a clear demand-side problem. Neither the construction nor the automotive industry can come to its rescue and solve this. But, a clear focus on sustainable infrastructure development could bring hope suggest the Greens. After all, renewable energies need a lot of steel they propose. A single 3MW wind turbine needs the same amount of steel as about 500 cars. Improving the energy performance in existing buildings by setting ambitious standards could lead to a veritable renovation boom that would be a boon for the steel industry. Fuel efficiency standards would also provide an opportunity for developing and selling new light-weight steel products as would hybrid and electric cars, all of which would help the European steel industry move into an increased value added speciality segment allowing it to open up and conquer new markets.

This discussion is certain to continue. To see the original article however visit http://www.euractiv.com/sustainability/europes-steel-industry-crossroad-analysis-532405

Dr Andrzej M Kotas

CEO

http://www.steelonthenet.com/

Labels: climate change, CO2 emission allowances, European energy prices, European steel demand, european steel industry, free CO2 allocation, steel industry overcapacity, value added steel production