Mittal and Arcelor - do they fit?

- FOR IMMEDIATE RELEASE -

London, U.K. - 30th January 2006 One thing you can say about the Mittal family is that they think big, and they never fail to surprise! The announcement of a bid for Arcelor came out of the blue for most industry analysts. Mittal’s strategy has always been to grow by acquisition – the world’s biggest producer has never yet built a steelworks – but the target this time was certainly unexpected.

The synergy

From an operational point of view, there are clear advantages to both companies in a merger of this sort. The regions of the world where they would have significant market share include the established markets of North America and Europe, together with the growing emerging markets in South America and Africa.

Mittal on their own just do not have the facilities in Europe to challenge the high-end auto market, despite making flat products in Romania, Poland and the Czech Republic.

Arcelor, on the other hand have only a small foothold in the North American flat products market and have little in-house supplies of iron ore. (This was about to change however – see below).

So, apart from in Asia, the two combined would be dominant in high-value production and this would be complimented by Mittal’s low-cost commercial steel production in central Europe and elsewhere. They would be getting closer to the “one-stop-shop” (though the value of this can be debatable).

One of the relatively few markets where they compete is in heavy sections in Europe. However, Mittal are meant to be closing their heavy section mill in the Czech Republic – as part of the restructuring plan agreed with the EU at accession.

In general, Arcelor have the “richer” product mix – with average revenues per tonne much higher than those of Mittal Steel. This is because around 70% of their output is flat products (much of it cold rolled) and stainless steels, whilst Mittal’s mix includes about 20% of low-value semi-finished products.

Another aspect of synergy is related to the availability of “in-house” raw materials. Along with their steel company acquisitions in Kazakhstan, Ukraine, North America and Bosnia Mittal obtained significant reserves of iron ore. They are actively planning new mines in Africa and South America. By contrast, and if the Dofasco bid does not go ahead, Arcelor have very little. This is an area where cost savings will occur – both through the redirection of raw materials as well as stronger purchasing power with respect to external suppliers.

What does it mean for Arcelor?

After a disappointing year when they failed to acquire Kryvorizhstal and (initially) Erdemir, things were just starting to go well for Arcelor. They came to a deal with Oyak, the buyers of Erdemir, for a minority stake and have just won control of Dofasco. These two investments give them an extension into other parts of Europe, complementing their existing facilities in Turkey, a foothold in the North American high-end market, and a source or iron ore in the shape of Dofasco’s Canadian mines.

In many ways, this gave them most of what they were looking for – certainly for now. A successful integration of these companies into their existing network would have reinforced their position as the world’s No 2 steel maker, and probably the world’s No 1 in the quality market.

What does it mean for Mittal?

Although there are significant gains for Mittal Steel, one cannot help wondering whether their bid is partly for defensive reasons. The last thing they wanted was Arcelor to win Dofasco – and the timing of the bid must have been affected by Arcelor’s success in beating TKS to this acquisition.

That said, they gain improved R&D and product development abilities as well as quality steel making in Europe. They also get a different image. Until now (and with some exceptions in North America) they have thrived on turning around bankrupt or poorly managed companies. They have done this very successfully, but the problem is that the flow of such companies has slowed in recent years as the transition process and related privatisations have dried up.

This has meant them turning to more established companies. If they had wanted to enhance their position in Europe, and had chosen Corus or Riva as their target, one would have been less surprised. Either would have led to an easier ride with competition authorities and would have been easier to absorb. Arcelor, on the other hand, is big and rather corporate in the way it operates. How the cultures blend together will be a key element of whether the bid (if successful) leads to extracting the promised synergy.

Arcelor’s board will be miffed that there was less communication prior to the announcement and this will make it more difficult to secure a smooth transition in the event of their offer being accepted by shareholders.

What does it mean for the industry?

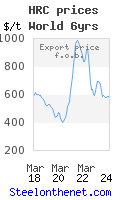

For years analysts have been complaining of the lack of consolidation within the industry. Lack of production discipline during times of weak demand is certainly one of the reasons for volatile prices. Any increase in consolidation may therefore benefit the whole industry.

It will also spur on the other big companies to look for suitable partners. The world has four main regions when it comes to steel production.

China is obviously the largest and will not be greatly affected by the merger. (Both companies have interests there but even when combined they will still be small players in the Chinese market.) If anything, it may encourage the companies and the Government to move faster in consolidating what is a very fragmented sector.

The big Japanese and Korean companies dominate the rest of Asia, albeit alongside many smaller producers. Nippon Steel, JFE and POSCO are all in the current top-10. They will be nervous that they are falling behind the global giants and, if the merger goes ahead, might be encouraged to forge links with a European or American producer.

Russia is still the big net-exporter of steel. It has cheap ore, coal and other energy and its companies are looking to expand beyond the region. They need good finishing end facilities - close to the market but where steel making costs are high. They will either look to pick up smaller stand-alone mills, or integrated companies where it might be advantageous to close their heavy end.

Finally there is the rest of the world. The big companies are Corus, TKS, and Riva in Europe; Nucor and US Steel in North America; and Gerdau in both North and South America. These companies will certainly be looking for partners in the coming months and years in order to be able to compete with the potential new giant.

So, do they fit?

The answer, of course, is yes in many ways: certainly in terms of geographical and product coverage, and certainly in terms of the raw materials benefits accruing to both companies.

On the other hand, the Group will be “big” but not terribly “focussed”. Arcelor have in the past valued their focus, perhaps more than anything, whilst Mittal have been prepared to produce any steel product that can turn a profit.

As, described above, the irony is that Arcelor were just getting their act together in terms of increasing their size but retaining their focus. They will fight hard to promote that vision to their shareholders.

- PRESS RELEASE ENDS -

See original press release from GSC

For further information, contact: gsc@steelonthenet.com

Press enquiries: +44 (0) 1737 358 625

Mr Mike Mytton

Global Steel Consultants

http://www.globalsteelconsultants.com

NOTES FOR EDITORS

About Global Steel Consultants

Global Steel Consultants is a network of independent steel advisers who specialise in strategic planning, steel restructuring, due diligence and project appraisal for an international client base. For further information, please contact: info@globalsteelconsultants.com.