How to Get the Most from Steel Industry Management Consultants

Introduction

In today’s rapidly evolving steel sector, partnering with steel industry management consultants can provide significant competitive advantages. From operational efficiency to strategic growth, expert consulting offers unique insights that are hard to achieve in-house. But how do you ensure you're getting the most out of your collaboration with steel consultants? In this article, we explore actionable tips and strategies for maximizing the benefits of working with these industry experts.

For top-notch consulting services, explore the offerings at Metals Consulting International.

1. Why Hire Steel Industry Management Consultants?

Steel industry consultants bring specialized knowledge and deep market insights, which can greatly enhance operational decision-making. Whether you're seeking improvements in production processes, supply chain management, or cost optimization, partnering with experts allows you to tap into the latest technologies, methodologies, and best practices.

2. Key Areas Steel Consultants Can Help With

When you work with steel industry consultants, you’re not just hiring general business experts. These professionals specialize in:

- Operational Efficiency: Optimizing steel production workflows.

- Supply Chain Management: Streamlining procurement and logistics.

- Cost Control: Reducing raw material and labor costs.

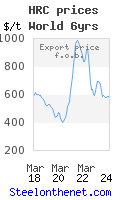

- Market Analysis: Providing up-to-date market trends and pricing forecasts.

To get tailored advice, consider visiting Metals Consulting International.

3. How to Choose the Right Steel Consulting Firm

Not all steel management consulting firms are created equal. It’s important to evaluate potential partners based on:

- Experience: Choose firms with a proven track record in the steel sector.

- Customization: Look for consultants who offer solutions tailored to your specific challenges.

- Data-Driven Approach: Firms that utilize the latest data and market analysis tools can help your business stay ahead of the competition.

MCI offers decades of industry experience and customized solutions for businesses of all sizes. Learn more - check out the MCI brochure.

4. Maximizing ROI with Steel Industry Consultants

To get the most value from steel industry management consultants, consider the following strategies:

- Set Clear Objectives: Before engaging with a consulting firm, outline what you hope to achieve.

- Engage Regularly: Keep communication lines open and ensure regular updates on project milestones.

- Implement Recommendations Quickly: Ensure your team is ready to implement changes recommended by consultants.

The team at MCI is equipped to help you through every stage of the consulting process, ensuring that you achieve measurable results.Visit Metals Consulting International to learn more.

Conclusion: Transform Your Business with Steel Industry Experts

Steel industry management consultants offer more than just advice; they can transform your operations, boost profitability, and ensure long-term success. By choosing the right consultants and actively engaging with their recommendations, you can unlock new opportunities in this competitive market.

Looking for trusted consulting services? Email us at info@metalsconsultinginternational.com or call _+44 775 149 0885.

Labels: advisors, feasibility assessment, management consultants, market experts, MCI, Metals Consulting International, steel consultants, steel industry consultants, technical support